Fall Field Work Following a Wet October

As of October 31, 81% of the 2021 Illinois corn crop and 75% of the soybean crop had been harvested. That’s close to the 5-year average for corn, but 11 percentage points less than the average for soybeans. While harvest started early and with low grain moisture, much of Illinois, with the exception of the southern third of the state, received 6 to 10 inches of rainfall (2 to 6 inches above normal) in the last three weeks of October. As a result, harvest progress slowed to a crawl.

Harvest: Ruts or Not?

The first concern for many people is getting the rest of the crop harvested. While some soybeans have dark color from staying wet so long, seeds mostly remain in pods, and they should be harvestable as soon as combines can get through the field. Some corn is badly lodged, but ears are intact for the most part, and should, with patience, be harvestable as well. The cool temperatures this week accompany the welcome return of days without rainfall, but with daily low temperatures around 30 and daily highs in the 40s, soils are not drying very quickly. Water will continue to drain downward from soils, but surface soils may not get much drier than field capacity (soil with the amount of water held against gravity) at these temperatures.

It can be difficult to wait until soils are dry enough so the combine doesn’t cut ruts, and some will likely decide that cutting ruts is preferable to waiting longer to harvest soybeans. If there are only a few small places in a field where water stood (or is standing) and where ruts are likely, that’s probably reasonable. It may still make sense to stay out of the wettest spots, especially if there’s any danger of getting the combine stuck. If the whole field is a “low spot,” it may be better to wait until the surface soils are dry enough to support the weight of the combine.

Contrary to what many believe, driving heavy equipment on soils wet enough to result in ruts is not the “best” way to cause soil compaction. Compaction is the removal, via mechanical pressure, of air from pore space in the soil, in the process increasing the bulk density (dry weight per unit of volume) of the soil. Water occupies most of the pore space is soil where water has been standing, and because water can’t be compressed, saturated soils can’t be compacted. Saturated soil can be squeezed to the surface by tires to create ruts. But the mud that’s squeezed to the surface may not be seriously compacted.

In contrast, soils at field capacity, with air in about half their pore space and water in the other half, are at or close to maximum “compressibility”—they can be compacted to the maximum extent for that soil. Drier soils, with more mechanical strength to resist compaction, provide the best defense against compaction. In practical terms, while ruts look bad and can interfere with getting next year’s crop established, driving a combine or grain cart over fields that support the weight but that make tracks instead of ruts often means that more compaction has been done, even if it’s not as visible.

If we can’t avoid making ruts, it’s probably be best to postpone “rut repair” (secondary tillage to even the surface for planting) until next spring, since trying to do that this fall will generally mean scraping wet soils into the ruts; that might look better but will insulate the ruts from drying out faster next spring. The (partial) fix for compaction is deep ripping, but it is highly unlikely that soils this fall (or next spring) will be dry enough 12 to 15 inches deep to allow compacted layers to shatter in order to restore air content. We may simply have to live with compaction, as is often the case, and hope that our “forgiving” soils can forgive once again. Lowering combine tire air pressure or using wider tires, dual wheels, or tracks will lower the pressure on soil, and can decrease the degree of compaction.

Nitrogen application

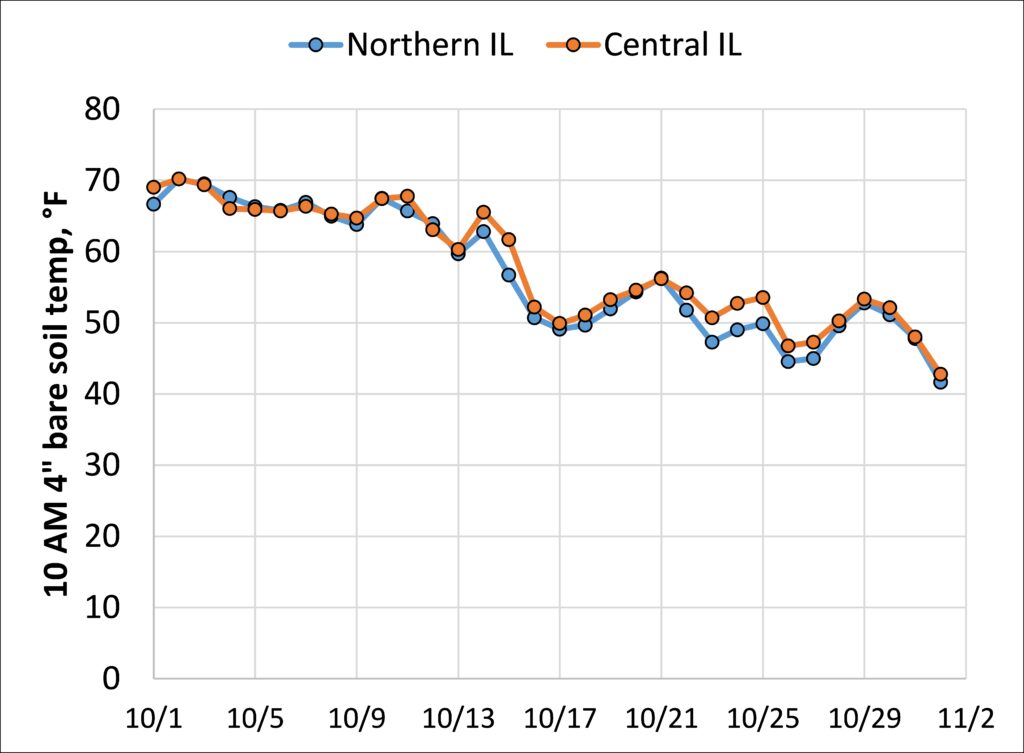

While there’s little positive about a wet October, it did put a stop to application of anhydrous ammonia while soil temperatures were still too high to make that a safe practice. Figure 1 shows that soil temperatures in central and northern Illinois dipped after October 25, rose again as rain fell for several days, then dropped as rain ended and air temperatures dropped as the month ended. We expect these to drop further as minimum air temperatures drop below 30 degrees this week. Although there’s no guarantee that they won’t rise again later in November, we can consider soil temperature low enough now to allow ammonia application to begin once this year’s crop has been harvested, and once soil conditions permit.

While soil temperature may be low enough to allow fall anhydrous ammonia application, soil conditions are not yet suitable in most fields. It makes little sense to “mud in” ammonia, when doing so results in ruts or tracks as discussed above. Ammonia injection into wet soils isn’t the problem: ammonia is so soluble that it may travel only an inch or two after release before it’s fully dissolved in the water in wet soil. That means a higher concentration of ammonia in the band, and a higher concentration of the nitrification inhibitor applied with the ammonia. Higher ammonia and inhibitor concentrations should delay the beginning of nitrification, even if soil temperatures rise again before eventually freezing. This is not the case with ammonia applied into dry soils followed by a lot of rain: such ammonia moves farther and is less concentrated, and any that went on earlier in October was applied into warmer soils.

While applying ammonia into wet soil might make it a little safer from nitrification and possible loss, the negatives of driving over wet soil to apply ammonia rule out doing this. One additional drawback to application in wet soils can be lower availability of the N to next year’s corn crop. If we apply using RTK to put the ammonia band a uniform distance (6 inches or so) away from next year’s seed row, this is not a problem. But if ammonia is applied on a slight angle, the distance between the row and N band varies from zero to half the width of the row, and this could be problematic if the ammonia band is small and doesn’t disperse very much in the spring. Spring tillage could help alleviate this, if it’s done deep enough to redistribute some of the N.

The alternative to going into wet fields this fall is, of course, is to wait until next spring to apply N. This year, that may mean more uncertainty in terms of N supply and price. But we have had years when fall conditions allowed little NH3 application, and with the creativity and persistence of Illinois producers and retailers, we have never failed to get N on the next corn crop. There is no reason to expect anything different this time.

Tillage

Some of the stress that comes with wet fall weather results from our limited ability to do fall tillage, including strip-tillage, to help prepare fields for earlier warmup and planting next spring. When we drive heavy tillage equipment on soils that are at field capacity, however, it is easy to cause as much or more compaction as we relieve by doing primary tillage. So unless November miraculously turns out to be dry enough to allow soils to be in shape for deeper tillage (this would likely require warmer weather, which could put any ammonia at risk), it is probably best to avoid tillage this fall. Strip tillage may be possible if surface soils dry some. Surface soil drying might also allow shallow (or “vertical”) tillage to help size and bury corn stalks for faster breakdown in the spring. A lighter tractor with adjustments to limit compaction will help in that case, since soils are unlikely to be dry enough to avoid deeper compaction.

There is no known reason to even consider tilling soybean stubble this fall.